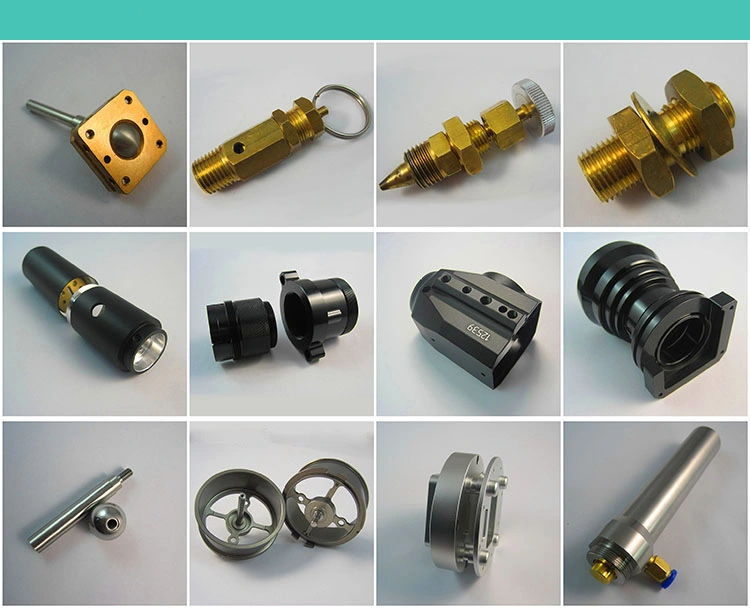

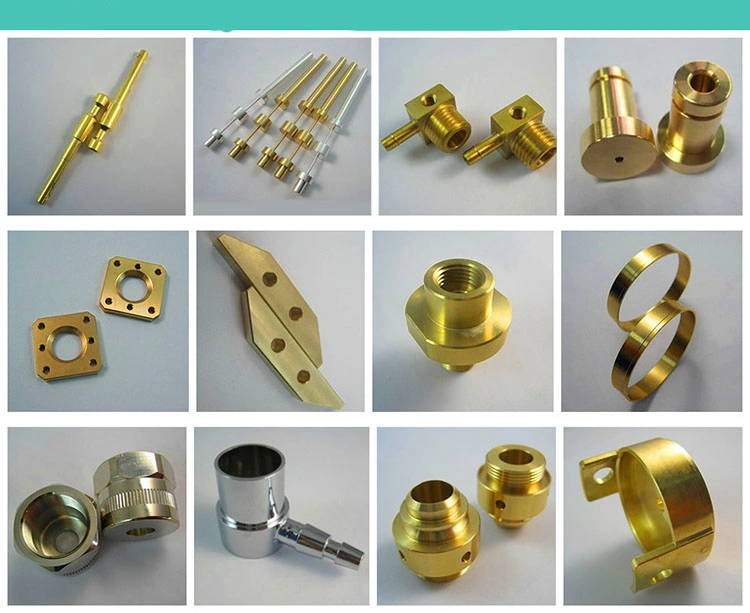

Custom Original Factory Machining Brass Material Parts Hardware Hydraulic Pneumatic Components

Title: cnc machining part, aluminum turning cnc machine part, cnc machining parts,original factory manufacturing OEM/ODM;

Basic Info.

| Model NO. | XR-0132 |

| Trade Term | EXW, Fob, Fac, CIF, CFR |

| Machining Service | OEM |

| Drawing | 2D/3D |

| Tolerance | ±0.01-±0.005 |

| Processing | E.D.M, CNC Turning, Milling, Grinding, Cutting |

| Payment Term | T/T, L/C, D/P, D/a |

| Transport Package | Sponge with Plastic Bag, Outpacking: Cartons |

| Specification | Customized |

| Origin | China |

| HS Code | 73261910 |

| Production Capacity | 500000PCS/Year |

Product Description

Title: cnc machining part, aluminum turning cnc machine part, cnc machining parts,original factory manufacturing OEM/ODM service.| Type | Welcome all inquiries, requirements and customized orders |

| Processing | According to your drawing or picture or samples , .PDF .DWG .IGS etc |

| Material | Stainless steel , Brass , Copper , steel , POM , Nylon 6 ,Plastic , |

| Standard | no |

| Tolerance | ISO 9001 , +/-0.05mm |

| Surface treatment | Sand blasting+anodzing , Zinc plated , Nickel plated , chromeplate , Anodized , Black oxide finish |

| Used | All kinds of cars, machinery, home appliances, electronic products, electric appliances,stationery, computers, power switches , Medical Equipment etc. |

| Machining equipment | CNC machining center, grinding machine, milling machine, drilling machine, horizontal milling machine, chamfering machine, Metal Stamping ,CNC cutting machine etc. |

| Advantage | All the order can custom |

| Good quality product and high precision | |

| Delivery | 3 -5 days for samples |

| 20-25 business days for Production time | |

| Payment terms | T/T L/C |

| Ports | ShenZhen China |

Product Show

Company Information:

XingRui Precision Mould Co.,Ltd is an processing enterprise to produce hardware mould and plastic mould precision fittings professionally.we can meet users diversified and special production requirements comprehensively by tens of years of experince by relying on shound management,excellent technology and processes,we also can provide complete tungsten steel solutions for users especially by breakthrough in tungsten steel parts processing field.Our company has the most advanced processing process in tungsten steel punch,bushing,and special forming punch,stator,special rotor punch and die,tungsten steel mechanical parts,ceramic mould parts and other fields in the same industry for a long time,we have more unparalleled advantages when guaranteeing high quality and synchronous delivery.Over the years we cntinue to invest in precision plastic plastic mould parts and automation equipment,introduce advanced CNC equipment and cultivate various kinds of excellent talents to completely support the continuous of company's development,now processing products of our company cover hardware mould,plastic mould,electrical and electronics,automotive,stationery,medical equipment and mechanical parts and other industries,company achievements also increase steadily,Our company always insists in "the best quality,the fastest delivery,the most reasonable price and the most attentive service"to thank new and old users for their support and help.

Shipping&Package:

Shipping:*If the quantity is not big or you need it urgently,We advise you to ship them by Express such as DHL,FEDEX,UPS,TNT,EMS,etc.*If your quantity is large,We advise you to use sea shiping or Air shipping.And the sea port is in Shen ZhenPackage:Full consideration of actual situation: foam/wooden box, anti-rust paper, Anti-rust oil+plastic bag+carton, or as per clients' requirments.

Why Choose Us:

* - Quality: Qualified raw materialsIntegrated production line machineMature processingSkilled employeeStrict quality control* - Price: competitive price / reasonable margin* - Service: Any inquiry will reply within 24 hoursAny question will give a satisfactory answer.Fast deliveryQuick ReplyWarranty: depending on product type

You may also like

Send inquiry

Send now